This guide provides different methods of lashing and how they can best suit and secure your cargo. We value your products and want them to arrive to your final destination in the safest way possible. By preventing sliding, shifting, and rolling of your cargo during the shipping process, we can ensure the best possible delivery at your destination.

What is a container lashing?

When containers are loaded on ships, it gets secured to the structure of the ship. Lashings help prevent the containers from moving or falling.

Why is securing your cargo important?

Improper securing can cause your container to slide, tip, roll, or fall which can cause damage to your contents. The point of securing your cargo is to keep the contents from shifting inside the container.

Some ways to help secure your cargo are:

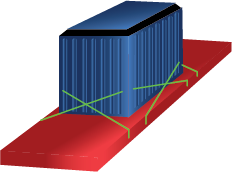

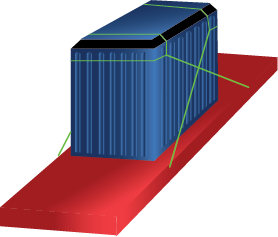

Direct Lashing Against Sliding: Direct lashing against sliding is when anchor points on the cargo that can be used to secure the cargo directly to the base. This is important as it eliminates sliding for all sizes of cargo during transit.

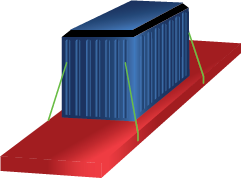

Direct Lashing Against Tipping: Direct lashing against tipping is when there are anchor points on the cargo that can be used to secure the cargo directly to the base. This is important as it eliminates tipping during transit.

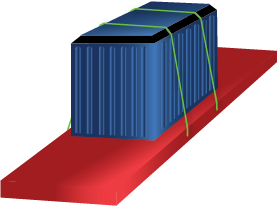

Top Over Lashing: Top over lashing is best used to prevent tipping but it is important to note that it cannot eliminate sliding and shifting during transit. This method works well for single items but never with stacked cargo.

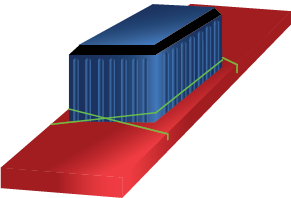

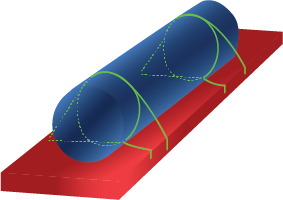

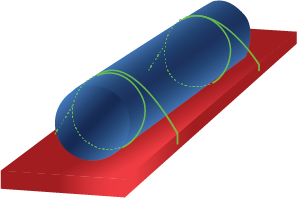

Horizontal Half-Loop Lashing: Horizontal half-loop lashing prevents sliding and shifting, it is best used with low center of gravity cargo without anchor points. The lashings do not go over top like the spring lashing method.

Spring Lashing: This is a method used when the cargo has no points that can be directly fastened. It provides stability when it comes to sliding, shifting, while reducing the risk of tipping.

Vertical Half-Loop Lashing: Vertical half-loop lashings are best used when the cargo has no anchor points, however; sliding and rolling is prevented much more compared to silly-loop lashing.

Silly-Loop Lashing: Silly-loop lashing provides no direct support between the cargo and the base. The cargo is still able to slide on the base, but due to it wrapping under the cargo, sliding is minimal. Stacking is not recommended.

Recent Comments